Concrete is one of the most commonly used building material in the construction industry today, although it is a relatively new material. Concrete's make-up is a mixture of several ingredients - cement, sand (fine aggregate), coarse aggregate and water - in varying ratios depending on the desired aim: strength or economy.

Cement acts as the bonding agent. In fact, hardened concrete is formed because of a chemical reaction between water and cement in a concrete mixture. A wet construction site will thus be advantageous because then the setting concrete need not be covered with a wet cloth to preserve moisture.

Here are some illustrations on how concrete is used in floor construction:

Ground floor construction.

Ground floor construction.

Upper floor construction.

Concrete can be moulded into practically any form, as it mimics the shape of its formwork; it can even be pumped and laid in various different, difficult positions.

Advantages:

- Durable

- Fire resistant

- High compressive strength

- Low maintenance

- Not affected by corrosion

- Not susceptible to insect attacks

- Easy to handle when batching and mixing

- Reasonable price (economical)

- Widely available

Disadvantages:

- Low tensile strength, cracks easily

- Fresh concrete shrinks upon drying (water evaporates), while hardened concrete expands upon contact with moisture

- Concrete expands and contracts with changes in temperature

- Concrete will disintegrate under alkali and sulphate attacks

- Lack of ductility - unsuitable for earthquake-resistant designs

The quality of concrete depends on:

- The quality of its ingredients

- The batching and mixing ratios

- The grades of aggregate used

- The amount of water used

- The quality of the compaction process

- The curing process

There are several types of concrete available for use. Some of them are:

- In-situ Concrete

- Pre-cast Concrete

- Pre-tensioned Concrete

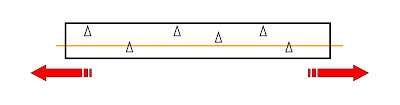

Step 1: Stretch the steel pre-stressing strands tightly across the casting bed.

Step 2: Cast the concrete around the strands and left to cure, during which the concrete will bond to the strands.

Step 3: After the concrete has adequately cured, cut the strands. The concrete will go into both compression and tension simultaneously. This will increase its strength.

BOOGA~~~ nice 1....still dun get wats pre-tensioned concrete though....but then agn...thumbs up for ur bloggie....and btw how long is ur posts?? weekly?? daily?? or randon timing??

ReplyDeleteWhich part don't you understand? We'll try to answer the best we can =) But for now, all we can say is that the steel pre-stressing bars are a little - a LITTLE - like rubber bands. Cuz remember in Step 1 they get stretched? After they are cut in Step 3, there is nothing to hold the strands in their stretched state...so they will shrink back more or less to their original size (not a fast process...). It's not back 100% though. Just like rubber band, once you stretch it for looong time it won't entirely resume its small shape =)

DeleteBut since the concrete has bonded with the steel strands, they will follow the new shrunken shape and curve upwards if there is no load imposed on the concrete (refer to diagram in Step 3). It is when there is load...like humans, furniture etc on top that provides compressive strength (push things downwards - think weight + gravity!), that the concrete resumes its correct horizontal form.

The rest I think has been explained by my fellow groupmate...I hope you understand it better now? If not feel free to ask again and we'll try once more. Lol.

Um we will try to post at least once every few days, but as students I can safely say 'random timing' is a safer answer XD Hahaha!

Stay tuned, Manji! Till next time then.

Prestressed concrete is a method for overcoming concrete's natural weakness in tension. It can be used to produce beams, floors or bridges with a longer span than is practical with ordinary reinforced concrete. Prestressing tendons (generally of high tensile steel cable or rods) are used to provide a clamping load which produces a compressive stress that balances the tensile stress that the concrete compression member would otherwise experience due to a bending load. Traditional reinforced concrete is based on the use of steel reinforcement bars, rebars, inside poured concrete.

ReplyDeletePre-tensioned concrete is cast around already tensioned tendons. This method produces a good bond between the tendon and concrete, which both protects the tendon from corrosion and allows for direct transfer of tension. The cured concrete adheres and bonds to the bars and when the tension is released it is transferred to the concrete as compression by static friction. However, it requires stout anchoring points between which the tendon is to be stretched and the tendons are usually in a straight line. Thus, most pretensioned concrete elements are prefabricated in a factory and must be transported to the construction site, which limits their size. Pre-tensioned elements may be balcony elements, lintels, floor slabs, beams or foundation piles. An innovative bridge construction method using pre-stressing is the stressed ribbon bridge design.

nice! =)

ReplyDeleteThank you, please stay tuned for more =)

Delete